This article is in a state of significant expansion or restructuring. You are welcome to assist in its construction by editing it as well. This template was placed by Fred Hsu (talk · contribs). If this article has not been edited in several days, please remove this template. If you are the editor who added this template and you are actively editing, please be sure to replace this template with {{in use}} during the active editing session. Click on the link for template parameters to use.

This article was last edited by Fred Hsu (talk | contribs) 15 seconds ago. (Update timer) |

Contributor note: The article has been rewritten and expanded recently. It is near book-length now, and is undergoing the next transition to split it into linked child articles. Please see the Talk page for details. |

Inline skates are boots with wheels arranged in a single line from front to back, allowing one to move in an ice skate-like fashion. Inline skates are technically a type of roller skate, but most people associate the term roller skates with quad skates, another type of roller skate with a two-by-two wheel arrangement similar to a car. Quad skates were popularized in the late 19th and early 20th centuries. Inline skates became prominent in the late 1980s with the rise of Rollerblade, Inc., and peaked in the late 1990s. The registered trademark Rollerblade has since become a generic trademark due to its popularity. To this day, "rollerblades" continues to be used in everyday language to refer to inline skates.

In the 21st century, inline skates come in many varieties, suitable for different types of inline skating activities and sports such as recreational skating, urban skating, roller hockey, street hockey, speed skating, slalom skating, aggressive skating, vert skating, and artistic inline skating. Inline skaters can be found at traditional roller rinks, street hockey rinks, skateparks, and on urban streets. In cities around the world, skaters organize urban group skates. Paris Friday Night Fever Skate (Randonnée du Vendredi Soir) is renowned for its large crowd size, as well as its iconic +10 mile urban routes.[1][2] Wednesday Night Skate NYC is its equivalent in New York City, also run by volunteers, albeit smaller in size.[3][4]

History

[edit]The documented history of inline skates dates back to the early 18th century, when enterprising inventors sought to make boots roll on wheels to emulate the gliding of ice blades on dry land. Because these wheeled skates were modeled after ice blades, their wheels were arranged in a single line. Skates were simply assumed to have a single runner, whether it was a steel blade on an ice skate or a row of wheels on a wheeled skate.[5]

The first patented wheeled skate was filed in France in 1819 by Charles-Louis Petibled.[6] From that point forward, more patents and documented designs continued to explore wheeled alternatives to ice skates.[7] Around 1960, wheeled skates began to gain popularity, and new patents appeared under names such as roller-skates and parlor skates. As inventions increased, roller skates began to diverge from the original single-line layout.[8] Inventors experimented with two rows of wheels as a learning platform for beginner skaters.[9] These double-row skates offered greater stability, but they were difficult to turn.[10]

In 1863, James Plimpton invented a roller skate with four wheels arranged in a two-by-two configuration, similar to a wagon, and added a clever mechanism for turning.[11] It was the first double-row skate that allowed beginners to steer easily by simply leaning in the desired direction.[12] Plimpton's invention sparked a rapid rise in roller skate popularity and spread across both sides of the Atlantic, creating a period of "rinkomania" during the 1860s and 1870s.[13] His design also redefined the term roller skate, which no longer referred to all wheeled skates but became synonymous with the two-by-two Plimpton style.[A]

The development of precision ball bearings in the mid-19th century helped make bicycles more efficient and practical.[15] By the 1880s, Plimpton-style roller skates similarly incorporated ball bearings into their wheel assemblies, making skates roll more efficiently.[16] At the same time, manufacturers began operating skating rinks as promotional ventures from the 1880s through the 1910s. All of these further fueled the Plimpton skate craze.[7]: 19–20, 25

Although Plimpton's roller skates took center stage, inventors and enterprises continued to introduce new roller skates with a single line of wheels between the 1870s and the 1910s.[17] These models included features such as brakes, pneumatic tires, and foot stands placed below the center of the wheels.

From the 1910s through the 1970s, many new variations of single-line wheeled skates were patented and manufactured.[18] While still in the shadow of 2x2 roller skates, some models began to gain popularity among ice hockey players by the 1960s and 1970s, due to their better emulation of ice blades. In particular, off-season training skates used by USSR speed skaters inspired Gordon Ware of the Chicago Roller Skate Company to develop and patent a wheeled skate,[19] which was sold through Montgomery Ward in 1965 under the name "Roller-Blade".[20][B] In 1973, Ralph Backstrom promoted the Super Sport Skate,[21] a joint venture with his friend Maury Silver, as an off-season training tool for hockey players.[22][C] Both of these skate models became direct precursors to modern inline skates.

In a related development, the ski boot manufacturer Lange introduced the first molded plastic ski boots with internal liners in the 1960s.[24] In the 1970s, Lange entered the ice hockey market with similar hard plastic boots featuring hinged cuffs and achieved some success.[25] Meanwhile, skateboarding reached new heights during the 1970s, thanks to the introduction of polyurethane wheels and their superior performance.[26] The confluence of molded plastic boots with hinged cuffs, polyurethane wheels, Super Sport Skates, and the earlier Chicago Roller-Blade laid the foundation for the emergence of Rollerblade in the 1980s and its widespread appeal among the general public.[27]: 12–16 [20]

In 1979, Scott Olson, a hockey player from Minneapolis, discovered the Super Sport Skate. He began selling them to local hockey players as a licensed distributor and soon started modifying them.[28] Olson, his brothers, and his friends replaced the stock boots with customers' old hockey boots and swapped out the original wheels for polyurethane ones.[29] Through further tinkering, prototyping and road testing everywhere he could, Olson eventually arrived at a skate design with an adjustable/expandable frame, polyurethane wheels and double ball bearings.[30] The skate rolled faster, and remained more reliable on road surfaces. However, a patent search revealed that the Chicago Roller-Blade already covered many of these features. In 1981, Olson persuaded the Chicago Roller Skate Company to transfer the patent to him in exchange for a share of future profits.[31]

Thus began the modern history of inline skates, with Olson's company eventually becoming known as Rollerblade, Inc. by around 1988.[32] The registered trademark "Rollerblade" became so well-known that it entered common usage as a generic term.[33][34] Around this time, the company began promoting the term in-line skating in an effort to prevent "rollerblading" from becoming a verb.[35] The campaign proved effective, as media outlets, newspapers, and competitors adopted "in-line skating" as the preferred term by 1990.[36] The phrase was soon shortened to inline, the name by which these skates are known today.

Modern inline skates became practical for mass production and appealing as a recreational activity once key technologies came together. These included polyurethane wheels, ISO 608 standard ball bearings, and molded plastic boots. These skates incorporate double ball bearings with dual-purpose axles from Chomin Harry (1925), single-piece frames from Christian Siffert (1938), adjustable wheel rockering from Gordon Ware (1966), single-unit boot/frame, longer frames and larger wheels from Maury Silver (1975), plus additional innovations.

Design and function

[edit]Anatomy

[edit]

All modern inline skates share a common basic blueprint. A skate comprises a boot, worn on the foot. To the bottom of the boot is attached a frame, the most rigid part of the skate. The frame holds a number of wheels in place with wheel axles. In between a wheel and an axle are two bearings. Bearings allow a wheel to rotate freely around its axle. Finally, a rubber brake typically attaches to the frame of the right boot, on recreational skates.[27]: 17–27 [37]: 14–39 [38]: 41–51

For many skaters, the frame is never removed or replaced. But wheels are consumables, as they wear down with use, and require periodic mounting rotations and even replacements.[33]: 81–86 Inline skates usually come with a skate tool for wheel, bearing and frame maintenance. The tool will have a hex wrench or a Torx wrench for removing wheel axles from a frame, and wherever applicable, for removing bearings from a wheel, and for removing a frame from a boot.[39][27]: 39–45 [37]: 39–51

In the 1980s and 1990s, all inline skates had hard boots, borrowed from ski boot designs. A removable liner in a hard boot provides a snug yet comfortable fit between a skater's foot and the hard shell. Around 1996, K2 introduced soft boots with an exoskeleton. These provide the most comfortable fit, at the expense of reduced rigidity. In the 2010s, hybrid (soft) boots with an endoskeleton were introduced to the high-end market. A hybrid boot has an integrated, non-removable liner. This is glued to a rigid endoskeleton shell integrated with the sole, providing direct power transfer from the foot to the wheels.[40]: 142 [41][42]

All three types are able to secure a foot in them without slack, with proper closure systems. Soft boots are often laced, and hard shells are usually secured with buckles. Velcro straps are also common in all types of boots. Well-designed boots provide proper heel support and ankle support to a skater.[37]: 14–39 [38]: 47–52 [40]: 142

The length of a frame positively affects stability and negatively affects turning agility. Longer frames accommodate more wheels, and taller frames larger wheels; both positively affect top skating speed. Modern inline skates are equipped with polyurethane wheels. Softer wheels provide a better grip on smooth indoor surfaces, while harder wheels wear down less on rough outdoor surfaces. Beginners skate with all wheels touching the ground, for enhanced stability, known as a "flat" wheel setup. Advanced skaters may choose to configure wheels in a "rockered" setup for enhanced maneuverability. The weight of a skate is an important consideration for some disciplines. Lighter boots, frames, and wheels are preferred. However, weight reduction is only achieved with escalating costs and diminishing returns.[37]: 14–39 [43]: 19–33

Striding and gliding

[edit]Recreational inline skating involves a continuous interplay between striding and gliding. As one foot pushes laterally against the ground during the striding phase, it converts sideways force into forward momentum. Meanwhile, the opposite foot glides ahead, supporting the skater’s weight. These phases overlap fluidly, with each skate alternating between pushing and gliding in a coordinated rhythm that sustains forward motion.[44][38]: 57–75

These two movements place distinct and often conflicting demands on skate design. A powerful stride benefits from a large contact area between the wheels and the ground, maximizing friction for a more forceful push-off. In contrast, a smooth and sustained glide calls for minimal contact to reduce friction and rolling resistance. Much of inline skate design involves balancing these opposing requirements to achieve both propulsion and efficiency.[45][46]

Edging and turning

[edit]

Modern inline skate design was heavily influenced by ice hockey. Early inline skates from the 1980s aimed to replicate the feel of hockey skate blades, often using a rockered wheel setup to allow easier turning and quick directional changes. While slalom skaters relied on these rockered setups and hockey players made rapid turns using crossover maneuvers, recreational skaters soon realized that even a flat wheel setup could support effective turning, thanks to the grip provided by polyurethane wheels on pavement. As with ice skating, inline skaters could shift their body weight and apply pressure to one side of the skate to gradually turn while gliding.[33]: 81–86 [44][45][46]

This technique is known as edging, which involves tilting the skate to roll on one side of the wheels. Skaters use both sides of the wheels for different maneuvers. The inside edge refers to the side of the wheel facing the skater’s body, while the outside edge faces away. Edging is essential not only for turning but also for powerful stride pushes, which require a strong edge angle. Deep edging, however, requires proper support from the boot, frame, and wheels to prevent the foot from wobbling within the boot and to keep the wheels from sliding out from under the skater.[D][37]: 37–38 [43]: 19–24 [38]: 47–52 [37]: 19–20

Heel support

[edit]Heel support refers to the ability of a boot to keep a skater's heel comfortably seated and firmly locked down in the heel pocket of the boot, even during aggressive maneuvering.

A heel pocket is formed by the shell, inner liner and sole of a boot. A properly designed boot has a heel pocket that hugs the heel, with an anatomical contour. A proper closure system causes the "facing" (where eyelet tabs are) to push the instep against the heel pocket, preventing the foot from shifting or lifting during maneuvers. As a result, the heel remains in contact with the footbed at all times.[37]: 15–18

Heel lock

[edit]Proper heel lock serves as a stable foundation for the entire foot. It allows a skater to adopt an athletic stance for skating by flexing the lower leg forward, without raising the heel. A snug fit means reduced movement of the foot within the skate, and thus reduced opportunity for friction to cause blisters. At the same time, the whole skate becomes transfixed to the foot as an extension of it, allowing efficient strides with a faithful transfer of power from the foot to the ground.[47]: 35–36, 79–80

Ankle support

[edit]

Ankle support refers to the ability of a boot to prevent sideways movement of a skater's ankle and lower leg, while allowing the shin to flex forward into an athletic stance. In some skates, such as recreational and aggressive skates, this is achieved via a hinged cuff. In other skates, such as hockey skates, this is enabled by rigid, and anatomically shaped quarter panels that lock both ankle bones in place, from two sides, leaving the shin to freely pivot forward.[37]: 5, 15–18 [48][40]: 142 [49]

Proper ankle support allows a skater to keep a skate upright as a straight extension of their entire leg, when observed from the front. Without rigid support on both sides of the ankle, the foot may wobble within the boot, causing the skate to tilt inward or outward. This creates pronation, making it harder for a skater to glide on a single skate at best, and resulting in sprains and other injuries at worst.[50]

Forward flex

[edit]

A properly designed boot does not hinder the mobility of the ankle joint, allowing a skater to pivot the lower leg (the shin) forward, adopting a squatting (athletic) stance. This forward flex (or forward leaning) is known as dorsiflexion of the foot. It places the center of body mass atop the ball of the foot, a balancing skill crucial to most skating moves. Without such a squatting stance, the leg and the skate form a 90° angle, placing the entire body weight of a skater on the rear wheel of the skate. This is dangerous for a beginner because a small backward shift of the upper body will cause a skater to pivot their entire body on the rear wheel, and thus fall uncontrollably backward.[37]: 67–77 [38]: 57–59 [44]

Types

[edit]

There are a variety of ways to design and make modern inline skates. Different types of inline skates reflect needs specific to different inline skating disciplines, such as recreational skating, urban skating, roller hockey, street hockey, speed skating, slalom skating, aggressive skating, and artistic inline skating.

Manufacturers and resellers generally classify inline skates based on disciplines, such as aggressive skates, speed skates and hockey skates.[37]: 30–38 Some disciplines are not large enough to warrant their own classification. Thus, dissimilar disciplines with similar equipment needs are grouped under a single skate category. For instance, freestyle skating, slalom skating, wizard skating, city commuting, and urban skating may be crammed into a single "urban skates" category.[51] Then, there are the rest of skaters who casually skate, skate for fitness, or skate for cross-training. These purposes constitute 90% of actual inline skate sales. Skates suitable for these activities are often grouped together as "recreational skates".[41]

Recreational

[edit]Some makers refer to recreational skates as "fitness skates". Others split them into two or more categories: recreational, fitness, and cross-training. Usually, the fitness and cross-training categories reflect increasing cost and thus quality of skates.[E] Soft boots with an exoskeleton are usually the least expensive. Hard boots with removable liners are often priced higher. Hybrid boots with an endoskeleton are high-end models.[48][42]

This category can be better understood as "unspecialized" inline skates, or generic skates. All other types of skates can be thought of as specialized deviations from this basic type.[41] Recreational skates usually come with four wheels of average size, and a frame of average length, which is just slightly longer than the boot. This places the front wheel halfway ahead of the toe box, and the rear wheel halfway behind the heel pocket, a design that remained unchanged since Scott Olson's adoption of Super Sport Skate from 1979.[21] Recreational skates are equipped with heel brakes. These allow beginners to learn to stop rolling, with a simple pivot of a foot on its heel.[27]: 25–26, 44–45, 52–57

Aggressive

[edit]

Aggressive skates are the most specialized inline skates, in contrast to recreational skates. They are designed for one specific purpose only: grinds. Grinding is the art of sliding on street obstacles such as stairs, rails, benches, curbs, ramps and walls.[40]: 134–163 To support these stunts, aggressive skates are generally built with strong hard boots based on ski boots and bolted to thick frames which are fitted with the smallest wheels in all of inline skating.[52] To help a skater lock onto an obstacle of interest during a grind, an aggressive skate provides channels and surfaces such as H-blocks, frame grooves, backslide grooves, grind plates, soulplates, etc.[53] Transitioning between these stunts, a skater often jumps considerable heights, or rides down a long flight of stairs (known as stair bashing).[37]: 33, 156–168 Thus, aggressive boots are often fitted with shock absorbers to dampen shocks upon landing.

Rollerblade Lightning TRS has been widely credited for enabling aggressive inline skating as a sport, with its durable boot and nylon-reinforced frame.[54] Aggressive skates co-evolved with the discipline which started as inline stunts.[47]: 98–110 It then turned into streetstyle skating, and finally into aggressive inline skating. The word "street" in street-style meant that skaters performed tricks on and over street obstacles, following nomenclature from skateboarding.[27]: 6, 64–77, 170–174 Skaters grind on street obstacles (termed street skating), perform stunts at skateparks (termed park skating), and take to the air at the top of ramps (termed vert skating).[37]: 33, 156–168

Aggressive skates have standardized on UFS, the Universal Frame System. Most UFS frames accommodate small wheels up to 60 mm.[55] Some UFS frames with frame grooves and H-blocks are designed with thick walls to prevent wheel bites. allowing them to be used with a flat wheel setup.[53] Other UFS frames without prevention measures against wheel bites can be set up with an anti-rocker wheel configuration, with even smaller and harder "grindwheels" (or "antirockers") in the middle.[56] Some skaters go one step further, replacing the two middle wheels with non-rotating "juice blocks".[57]

The name "aggressive" has been controversial.[58] Many in the community call aggressive skating rollerblading (or simply blading), and thus members bladers.[41] Others call it aggro.[40]: 134–163 [F] Some skate manufacturers eschew the label "aggressive", choosing to market their aggressive skates instead as street skates or park skates.[59]: 40–41 [G]

Hockey

[edit]

In the 21st century, the boots used for inline hockey skates (roller hockey skates) are constructed using a process that differs significantly from those of other inline skates.[60] They are primarily produced by ice hockey manufacturers such as CCM, Bauer (Mission), True, and Marsblade.[37]: 37–38 [H] In many cases, the same boot is used across both sports, with either a blade holder for ice hockey or an inline frame for roller hockey.[I][J] As a result, inline hockey skates continue to rely on the rivet-based mounting system used in ice hockey, even though replaceable frame standards have become common in other skate categories.[55]

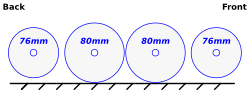

Hockey skates feature some of the shortest frames among all inline skates, enabling players to make tight turns and perform crossovers without interference. Hockey boots are designed to sit as low to the ground as possible, limiting them to smaller wheels. This configuration maximizes stability for hard edging maneuvers. Wheels with a rounder profile are preferred, as they offer improved grip and control during sharp turns at all edging angles.[43]: 19–24 [37]: 37–38 Many hockey skates use a hi-lo wheel setup, with larger wheels in the rear and smaller ones in the front. This raises the heel and lowers the toe cap, thus the name hi-lo. It causes a player to forward flex naturally, for greater stability and stronger strokes.[63]

The modern inline skate was originally created by Scott Olson as a substitute for ice hockey skates, featuring a boot with a hard shell, pivoting cuff, and removable liner.[33] This style of boot construction remains popular across all inline disciplines, ironically with the exception of inline hockey. Instead, hockey boots have followed their own path.[64][K] They are built to be as lightweight as economically feasible while still delivering excellent heel and ankle support, along with protection against impacts from flying pucks. Direct and immediate power transfer from foot to wheel is also essential. To achieve this, hockey boots are constructed around an unyielding wall with anatomical contours to hug the heel and both sides of the ankle. This structure is called the quarter package, made of left and right quarter panels bolted to a rigid outsole platform.[62][60] The rest of the boot is built around this base, including a thick tongue that supports the shin in a forward-leaning athletic stance, and a reinforced toe cap. The liner is integrated into the boot and not removable, with strategically varied thickness for best anatomical fit. Hockey skates are secured with eyelets and laces, rather than buckles or straps.[65][61]

Speed

[edit]

Speed skates (or race skates) are purpose-built inline skates with a single goal: speed. They enable a racer to generate the most efficient strides and to glide with the least amount of friction.[66]: 3–9, 283–318 Joey Mantia holds the world record for the outdoor 10-kilometers at over 27 miles per hour.[67]

Speed skating differs from other inline disciplines in that a speed skater tilts her body trunk forward for up to 60° when racing, to reduce air resistance. A speed skater bends her knees aggressively for up to 80° in a deep-seated squatting position which requires a deep forward leaning of the shin (dorsiflexion) for proper balance. This deep squatting posture produces the most powerful push-offs, with the farthest displacement of the pushing skate.[66]: 5–11

Because of the need for a deep dorsiflexion, speed skates have no eyelets, buckles, or straps above middle eyelets at 45° angle. In order for racers to freely flex their foot around ankle bones, speed boots are cut the lowest among all inline skates, around or below the ankle bones. The removal of shaft and cuff significantly reduces a boot's weight. [37]: 17, 34–36 [66]: 3–30, 308–311 Most speed boots are custom-fitted without much padding, or else heat-moldable, to prevent the foot from the slightest wobbling.[68][L]

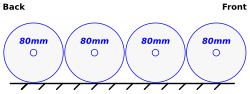

The frame may be made of aircraft-quality aluminum, magnesium, or possibly lightweight carbon fiber, such that it flexes very little and transmits power from the foot to the wheels more directly. The length and height of a frame determine the number and size of wheels it can accommodate. More wheels and bigger wheels increase mass, making acceleration harder and slower. But once rolling at speed, a skater can more easily maintain top speed given the rotational inertia. In the 21st century, wheel size ranges from 90 mm to 125 mm. A setup with four 110 mm wheels (4x110mm) is typical for competitive speed skating, and three 125 mm wheels (3x125mm) for marathon skates at marathon events.[37]: 18–24, 34–36 [70] Speed skates generally adopt either the 165mm or the 195mm mounting standard. Both of these 2-point mounting standards feature a built-in heel lift that pitches a skater forward, creating forward flex.[71]

Speed skating generally adopts harder and high-rebound wheels to minimize energy lost to elastic hysteresis. Speed wheels have a pointy bullet profile that reduces friction from drags when gliding upright, while still providing a large contact surface for improved traction and control when pushing off at a deep edging angle.[66]: 315–316 Speed skaters use High-quality bearings with precision ratings, and perform regular cleaning and lubrication to remove trapped dirt and restore them to their optimal performance.[27]: 128–130

Urban

[edit]

Urban skate is an umbrella term for a type of skate suitable for several niche inline disciplines: freestyle skating, slalom skating, wizard skating, city commuting, and urban skating. These activities take place on relatively flat ground, but the surface may not always be paved or smooth.[51]

Freestyle skating is named after its counterpart in skateboarding, just like aggressive street, park, and vert skating are named after street, park, and vert skateboarding, respectively. Freestyle skating is the art of performing skating tricks on relatively flat ground, free of obstacles.[72] Freestyle slalom skating is a form of freestyle skating where tricks are performed around slalom cones. This is standardized by the International Freestyle Skaters Association (IFSA) and World Skate as freestyle slalom to distinguish it from speed slalom, which is a form of speed skating around cones on flat ground.[73][74] Freestyle skating requires skates that support rigorous turning and edging maneuvers, with characteristics similar to hockey skates. A rockered setup with 76-80 mm wheels on a relatively short frame is common for freestyle skating.[75]: 15–25 [52]

Urban skating and city commuting take the activity to the street. But the term 'street skating' is already taken as a subdiscipline of aggressive skating, for grinding on street obstacles. Thus, this niche market is variously promoted as skating on paved roads or commuting to work on skates. These activities demand longer frames and larger wheels for higher cruising speed, stable tracking, and more comfortable rides on uneven surfaces, similar to speed skates for marathon events. Common wheel setups include 4x80mm, 4x90mm, 4x100mm, 3x100mm, 3x110mm, and 3x125mm.[51][52] Most urban skate boots support either the 165mm or Trinity mounting standard, and can be customized with a short frame and average-sized wheels for slalom skating, or with a long frame and large wheels for long-distance road skating.[55][76] Both the 165mm and Trinity mounting standards raise the heel mounting platform higher than the toe, creating a slight heel-to-toe drop, also known as a heel lift. This drop causes the skater to lean forward by default, simulating a subtle forward flex similar in purpose to the hi-lo wheel setup used in hockey skates.[55][77]

Wizard skating is named after the company Wizard Skating, founded by Leon Basin in 2014. This form of skating is characterized by flowing footwork from freestyle, slalom, and figure skating, while a skater blazes through roads, rolls over curbs, skates up ramps, bashes down stairs, and parkours on walls. Leon perfected a type of "Wizard" skate for this sport, featuring a long frame, large wheels, and a rockered wheel setup for either 4 wheels or 5 wheels.[78][52] Skaters are increasingly referring to this style as flow skating.[41]

Boots

[edit]Hard boots

[edit]Hard boots dominated the inline skate market in the 1980s and 1990s at the inception of modern inline skating. They are made of plastic, fiberglass, carbon fiber, or other solid materials. A removable liner in a hard boot provides a snug yet comfortable fit between a skater's foot and the hard shell.[48][42][79]

Hard boots use a combination of velcro straps and plastic buckles as closures. Some also use laces for the facing of the boot, while others have a front strap (or buckle) instead of or in addition to laces. The front lace and top buckle secure the foot inside the boot. To achieve proper heel lock, the liner is shaped to fit the heel, and the 45° strap (or buckle) presses the instep of the foot against the contour of the liner.[37]: 15–18

Hard boots have a high cuff (or shaft) to provide proper ankle support. In order to accommodate dorsiflexion, the cuff is made to pivot near the ankle bones. As a skater leans their shin forward, the hinged cuff rotates to follow the lower leg while continuing to provide lateral ankle support.[37]: 15–18

Molds used in plastic injection molding are expensive to make. As a result, plastic hard boots are usually available only in so-called "dual sizes". One hard shell is made for two US and EU shoe sizes (e.g. US 9-10, and EU 42-43). A thicker liner is provided for US 9 and EU 42 to fill the gaps, while a thinner liner is provided for US 10 and EU 43. Some manufacturers offer "dual fit" liners, where the same liner can accommodate two shoe sizes using elastic parts, memory foam, and other compressible space-filling materials.[48][37]: 15–18

Soft boots

[edit]

K2 introduced soft boots to inline skating in 1993 with its Exotech line of recreational skates, marking the company’s entry into the sport. Building on this innovation, K2 later released the legendary K2 Fatty, an aggressive skate featuring the same soft-boot design. Since then, similar soft boots have come to dominate the recreational skate market.[80][81]

They are akin to hiking shoes, made of textiles, mesh, neoprene, and other soft materials. Liners are integrated into the soft boot, and are thus not removable or replaceable. A soft boot is reinforced in strategic areas with a plastic exoskeleton for structural support.[42][79][37]: 15–18

A soft boot uses a pivoting cuff to support the lower leg, like hard boots. Otherwise, its exoskeleton covers only a small area of the foot. This allows the boot to provide superior airflow through its fabric for moisture extraction, to keep the foot cool.[48]

Soft boots use closure systems similar to those of hard boots. These include laces, velcro straps, and buckles. Lacing the front of the boot is key to securing the foot within the boot, due to the lack of exoskeleton support in this area. On the other hand, the flexible front of the boot readily accommodates different shapes of foot. Soft boots thus provide a more comfortable fit at the expense of reduced rigidity and support, making them suitable for beginners and casual skaters. Committed enthusiasts, however, generally avoid soft boots due to their lack of direct and immediate response to skating moves, a result of elastic hysteresis.[48]

Soft boots are lighter and generally more affordable than hard boots. They are also easier to manufacture in precise shoe sizes. While hard boots typically come in dual sizes, soft boots are available in half sizes for US shoe measurements (e.g., US 9.5, 10, and 10.5) and, in some cases, for EU sizes as well (e.g., EU 39.5, 40, and 40.5).[48][37]: 15–18

Hybrid boots

[edit]Hybrid boots, also known as hybrid soft boots, look superficially similar to soft boots, complete with soft materials covering a large part of the boot. Unlike soft boots, however, hybrid boots have no exoskeleton reinforcement apart from the pivoting cuff. These boots have an endoskeleton instead, in the form of a composite shell. The shell serves as the sole of the boot, with shell walls extending upward from the sole. The soft upper part of the boot is pulled taut over the shell and glued onto it.[42][48]

Hybrid boots are lighter than hard boots and soft boots. Yet they remain rigid where the foot meets the boot. Integrated liners in hybrid boots can be made thinner than removable liners in hard boots. In higher-end hybrid boots, the integrated liner is heat-moldable for the best custom fit, and the shell is made of carbon fiber. A hybrid shell sits much closer to the foot than a hard shell or the exoskeleton of a soft boot. As a result, hybrid boots provide more direct and responsive power transfer from a foot to wheels.[42][82]

Hybrid boots originated from the development of carbon shells in speed skates during the 1990s and 2000s. In the 2020s, manufacturers like Powerslide offer hybrid inline skates, including models such as the Hardcore Evo, Tau, and Swell. However, the term "hybrid" has yet to gain universal acceptance, and these boots are often marketed as high-end soft boots.[42][83][84]

One-piece carbon boots

[edit]

In the 21st century, hockey skates increasingly favor one-piece carbon boots with a monocoque shell that were first developed in the 1990s for speed skating. These boots are unlike the three common types of inline boots: hard, soft and hybrid. The one-piece boots are built around a carbon fiber-reinforced composite shell, where the shell almost completely surrounds a foot. After eyelet holes are punched out of a shell, the shell is usable as a functional boot if laced.[85]

For instance, Easton's Synergy 1300C came out in 2005, with a unitary shell made with carbon and aramid fibers. This is widely recognized as the first retail hockey skate with a composite shell.[86][87] Heat molding became possible in 2006, with the Easton Synergy 1500C.[88][89] Other hockey makers, such as VH Hockey, took it one step further, creating a single, unbroken composite shell that also incorporates the "facing" portion where eyelets are located.[82] A heat-moldable monocoque shell requires no breaking-in, unlike traditional hockey skates.[90]

True Temper Sports bought VH Hockey in 2016, and started to mass produce retail hokey skates with heat-moldable monocoque shells, as well as scaling up 3D scanning of feet at retail stores for custom True hockey skates,[90][91][92] leading to inline hockey skates such as the TF9 Roller Skate, and the TF Pro Custom Roller Skate in 2020.[93][94]

Frames

[edit]

An inline skate frame, sometimes referred to as the chassis in certain disciplines such as hockey[93], serves as the structural link between the boot and the wheels. It connects to the ground through the wheels mounted on it, and to the skater's foot through the sole of the boot.

Frame dimensions

[edit]Frame length, also known as wheelbase, refers to the distance between the centers of the first and last wheel axles. In disciplines like hockey and slalom, skaters use short frames with closely packed wheels to enhance maneuverability and enable fluid footwork. In contrast, speed skating relies on longer frames, which space out the wheels to provide greater stability at high speeds.[95]

Frame height, deck height, and ride height are related but loosely defined terms in inline skating. All three describe how low a boot can be positioned relative to the ground in a given setup, considering the number and size of the wheels. Ideally, a skater wants the boot as close to the ground as possible, while allowing enough clearance between the sole and the wheel tops for free rotation.[96][97] All three terms may refer to the distance from the frame's deck to the wheel axle center, excluding wheel size. In other cases, they are defined as sole-to-ground distance, incorporating both the structure of a frame and of actual wheel size.[M][95][98]

Frame rigidity

[edit]

Frame rigidity is essential for an efficient transfer of power from a skater's foot to the ground. A rigid frame does not suffer from elastic hysteresis.[37]: 18–21 For this reason, even entry-level inline skates often use fiberglass-reinforced plastic, instead or softer but cheaper plastic to make frames. For a stiffer yet lightweight frame, aircraft-grade aluminum alloys such as the 6000 and 7000 series are used. Hockey and speed skating often call for magnesium frames, which are even stiffer and lighter than aluminum. Some speed skaters use carbon fiber frames that are the most rigid and lightweight frames available.[55][99]

Rigidity of a frame is an important factor in choosing one. However, other considerations, including cost and weight, also influence the decision.[100] Sometimes, a discipline's needs trump many of these factors. For instance, aggressive skaters exclusively use fiberglass-reinforced plastic frames for their superior performance and consistent friction when grinding against all types of surfaces.[40]: 138 Some of the most rigid frames, such as those made of carbon fiber, can be too brittle for hockey. These frames shatter rather than deform under impact or extreme stress due to their low fracture toughness.[101] In addition, some skaters value comfort, which is at odds with rigid frames; increased rigidity transmits all imperfections of the road surface to the skater unattenuated, reducing comfort.[102]

Rockerable frames

[edit]Wheel rockering can be achieved by using wheels of different diameters, or by using a frame with built-in support for a rockered arrangement of identical wheels. Such rockerable frames may be configured in either a flat setup for long-distance skating, or a banana-rockered setup for highly maneuverable disciplines like hockey, with sharp turns and quick footwork.[33]: 81–86 [75]: 20–21

Some frames are compatible with toggleable hardware for quick and reliable switching of wheel setups. These involved the use of frame spacers, axle guides, mounting hole inserts, or axle bolts that fit oblong mounting holes in two or more ways, in order to shift the axle’s center to a preset position.[38]: 44–45 [N]

With the advent of mounting standards and easily-swappable frames in the 21st century, some inline frames now eschew toggleable hardware in pursuit of reduction in complexity, weight, and number of components. Each brand offers its own pre-rockered frame with custom axle holes to create a wheel arrangement that it deems optimal.[75]: 20–21 [104]

Non-standard frames

[edit]

Modern inline skates began as off-season training tools for ice skaters.[55] Early frames, including those used by the USSR speed skating team in the 1960s, featured adjustable lengths and variable wheel positions to fit different shoe sizes.[20] This approach continued in the 1966 Chicago Roller-Blade and early 1980s Rollerblade skates.[B][O] Early inline skates lacked mounting standards. The 1962 USSR skate and 1966 Chicago Roller-Blade fit flat-soled shoes, while the 1975 Super Sport Skate, modeled after hockey boots, used a raised heel mount that created a built-in heel lift.[C]

Non-standard frames still dominate entry-level skates and are often non-replaceable. Most lack adjustment for pronation or supination. Some, like the 2024 Powerslide One Zoom, use riveted frames that cannot be customized.[55] Outside the entry-level market, most inline skates follow one of three mounting standards: UFS, 165mm, or Trinity.[96][97] The exception is hockey skates, which still use riveted mounts like ice hockey boots. All hockey skates, from budget to hig-end custom models, have proprietary, non-replaceable frames.[H]

165mm and 195mm frames

[edit]

In 1974, Inze Bont, founder of the speed skate manufacturer Bont, created fiberglass-reinforced boots for short track racing, featuring 2 mounting holes spaced 165mm apart. An adjustable ice blade was attached to the boot using these holes. As inline skating gained popularity in the mid-1980s, companies like Darkstar, Mogema, and Raps began producing inline frames designed to mount onto these short track boots. This led to the establishment of the first inline skate mounting standard.[106][55]

The 165mm mounting standard incorporates a height differential of approximately 10 mm between the front and rear mounting points. This creates a heel lift, also known as pitch or heel-to-toe drop, allowing speed skaters to achieve more powerful push-offs through deeper dorsiflexion. Due to this height difference, the two mounting platforms on a frame are usually not contiguous. Other than the 165mm interaxial distance, the standard does not specify a frame width, mount width or exact mounting locations on the boot. In practice, Bont boots provide relatively small contact surfaces between the frame and the boot, compared to traditional rivet mounting. However, this is not an issue for rigid speed boots made from fiberglass, and even less so for Bont’s later innovations - kevlar boots (1986) and carbon fiber boots (1989).[71][95][55][107][108]

Roces Impala skates from the mid 1990s were the first to adopt the 165mm 2-point mounting standard outside of speed skating, paving the way for other inline skate manufacturers to follow. This standard became widely used across various inline skate disciplines, from recreational and aggressive skating to slalom skating. However, unlike speed boots, these disciplines do not rely solely on composite boots with extremely rigid soles. On softer soles, the small mounting platforms can cause the frame to wobble under load. To mitigate this, some boots reinforce the mounting areas with metal plates.[55][71][109][110]

The 165mm standard, also known as SSM (Standard Speed Mount), was developed when speed skates primarily used five small wheels (e.g. 5x80mm). However, as longer frames with fewer but larger wheels became popular (e.g. 4x100mm), the positioning of the mounting bolts interfered with some wheels, forcing frames to become taller. This increased a skate's center of gravity and reduced a skater's performance. Some speed frames relocated middle wheels or reduce their sizes to fit the standard.[70][107][109][71][66]: 311–316

To address this, the 195mm 2-point standard was introduced in 2003, also known as LSM (Long Speed Mount). By increasing the interaxial distance to 195mm, this standard prevented bolts from interfering with middle wheels, enabling the use of larger wheels and longer frames without increasing frame height. This design provides a stable ride at high speeds by maintaining a relatively low center of gravity in proportion to the longer wheelbase.[107][109][111][110][112]

The 195mm standard retains the same heel lift as the 165mm standard. In general, only speed skating boots use 195mm, while most other inline boots continue to rely on 165mm. However, many inline frames include dual mounting slots on the front mount to accommodate boots of either standard.[76][71]

UFS frames

[edit]The ESPN X Games introduced aggressive inline skating in 1995, propelling the sport into the spotlight. As its popularity grew, more enthusiasts took up aggressive skating, prompting companies to develop their own specialized skate lines to meet the rising demand.[113][114]

In 1996, K2 released the Fatty, a legendary skate that integrated the wheel frame into its soulplate for the first time. In this early stage of its evolution, the soulplate still consisted of two separate sections, a design inherited from riveted boots with separate toe and heel mounting platforms, as seen in the Rollerblade Lightning TRS. However, the K2 Fatty reduced the height difference between these mounting platforms, and eliminated the hollow between these two platforms. It frame was now shaped like a solid rectangular bar.[54][114][115]

In 1998, Roces too, released an aggressive skate featuring a combined soulplate and frame: the 5th Element. This design not only incorporated a rectangular frame without distinct mounting platforms, but also featured a completely flat soulplate with no height difference between the front and rear sections. This flat sole significantly improved soul grinding and was soon adopted by other skate manufacturers. Additionally, the 5th Element’s integrated soul/frame unit could be easily removed from the boot by loosening just three screws.[54][114][116]

In 1999, Salomon, along with USD, Razors, Kizer, 7XL/Able, and Fifty/50, collaborated to establish a standardized mounting system for aggressive skates: the Universal Frame System (UFS). This standard capitalized on the emerging trend of flat soulplates, requiring a single, flat rectangular mounting surface 41 mm wide and long enough to accommodate two mounting holes spaced 167 mm apart. In 2001, Salomon introduced the Aaron Feinberg Pro Model, the first skate to feature the UFS mounting standard. The model quickly gained popularity and set a new industry benchmark.[54][114][117][118]

Unlike other mounting systems of the time, UFS eliminated built-in heel lift, positioning the heel level with the toes for the first time. However, most brands followed Salomon’s lead in incorporating a thick shock absorber at the heel. This provided better impact support for hard landings from high jumps, but accidentally reintroduced a small amount of heel lift.[54][114][119]

Trinity frames

[edit]The 165mm mounting standard, originally from speed skating, has dominated the inline skate market since the mid-1990s, except in aggressive skates that use UFS mounting and hockey skates that rely on rivets. However, not all inline boots are made from the stiff carbon-composite materials typical of speed boots. The small 165mm mounting area can lead to frame wobbles on boots lacking a rigid sole or reinforced mounting platforms.[55][109]

As larger wheels gained popularity in the 21st century, 165mm frames evolved to accommodate setups with bigger and sometimes fewer wheels. Some manufacturers increased frame height, which negatively affected stability and performance.[111][109] Others relocated or downsized middle wheels to avoid interference with mounting bolts.[70][120] Some brands even shifted the mounting platforms forward or backward to fit specific wheel setups, causing front-to-back centering issues when mixing and matching boots and frames.[109][71] For instance, Rollerblade Twister and certain Seba boots have unconventional 165mm mount placements, making it difficult or even impossible to achieve proper longitudinal centering with aftermarket frames. To meet demand for these popular boots, Endless Blading released a version of its Endless 100 frame specifically tweaked to fit them.[121]

The 195mm standard, introduced in 2003, better supported larger wheel setups without increasing frame height, relocating middle wheels, downsizing middle wheels, or shifting mounts.[110][70] However, it also spread the mounting points farther apart – beyond the optimal heel-to-ball length that best supports an average foot. The 195mm standard required exceptionally stiff soles and boots, which were unavailable outside the speed skating market until the late 2010s. As a result, only speed boots made of carbon fiber adopted the 195mm standard.[70][122][123]

In 2016, Powerslide introduced the Trinity mounting system to accommodate a wide range of modern wheel setups while addressing the shortcomings of both the 165mm and 195mm standards. Demonstrating its versatility, Powerslide launched Trinity-mounted boots and frames across multiple disciplines, including recreational, urban, speed, slalom, hockey, and off-road skating.[124][107]

The name "Trinity" reflects its three mounting points, in contrast to the two-point systems used in 165mm, 195mm, and UFS. Trinity features two front mounting points positioned on the sides with a longitudinal offset, avoiding the centerline where the two frontmost wheels are located. The vacated centerline allows front wheels of any size or configuration to be placed within millimeters of the boot sole. The rear mount is elevated by 10 mm, creating a heel lift similar to the 165mm standard. Positioned under the heel and in line with the rear wheels, the rear mounting bolt remains unobtrusive due to the 10 mm rise. The longitudinal offset positions the two front mounts asymmetrically under the medial and lateral sides of the ball of the foot. The three mounting points create a triangular configuration with sides measuring 150 mm, 135 mm, and 55 mm. This design provides structural support tailored to a typical foot, ensuring optimal heel-to-ball alignment.[125][77][122][70][95]

A Trinity frame generally exhibits less wobble than 165mm and 195mm frames when comparing boots with similar sole rigidity and mounting platform strength. This is because a 165mm frame depends on the boot sole to function as a cantilever beam, with each side extending outward and applying bending forces to the centrally located mounting bolts. In contrast, a Trinity frame distributes structural support across the full width of the ball of the foot, much like a hockey blade holder with two front mounting wings. This broader support reinforces the sole and shortens its effective cantilever length on each side of the boot, resulting in better transfer of power from foot to wheels and support for weight transfer when leaning into an edge.[109][126][127][124]

A Trinity frame typically has a lower "front" mount height than its 165mm counterpart when using the same wheel setup. This is because the front mount of a Trinity frame can be positioned significantly lower than the tops of the front wheels due to its open centerline. However, a reduction in mount height alone is not a meaningful metric for skaters. The true advantage of a Trinity frame lies in its ability to position the front of the boot as close to the ground as the front wheels allow, effectively lowering the skate’s center of gravity. This improves control and stability, resulting in a safer and more responsive skating experience.[109][98][124]

Heel brakes and toe stops

[edit]A hard rubber brake attached to the heel of the frame, known as a heel brake, allows a skater to stop by lifting the toes of the skate and pressing the brake against the ground. Learning to use the heel brake is crucial for beginners, as it provides the easiest method to stop in emergencies and control speed on downhills. Recreational and fitness skates typically include one brake unit, which can be mounted on either the right or left skate. Most righthanded skaters choose to attach the brake to the right skate.[27]: 25–26

However, heel brakes can interfere with certain skating techniques. Hockey players and speed racers, for example, rely heavily on crossover turns, where one leg crosses over the other to execute sharp turns without losing speed. In such moves, a heel brake becomes an hindrance. Similarly, heel brakes limit a skater’s ability to perform freestyle slalom tricks and aggressive grinds. For this reason, specialized skates designed for racing, hockey, slalom, and aggressive skating generally do not come equipped with a brake.[128][37]: 30–38

Some urban skates come with a brake included in the box but left unattached, while others are not designed to accommodate a brake at all. Many intermediate and advanced skaters eventually remove the brakes from their recreational skates once they master stopping techniques that don't rely on them. Moves such as the T-stop are commonly used to slow down; one skate is placed perpendicular behind the other to form a "T" and increase friction. However, most braking maneuvers like these cause significant wear on wheels by grinding them against the ground. As a result, some skaters prefer to focus on obstacle avoidance using slalom techniques and controlled turns, which minimize wheel wear.[128][79][37]: 87–96, 101–114 [75]: 24

Inline figure skates are unique among inline designs in that they use a toe stop instead of a heel brake. Toe stops are essential for performing many artistic roller skating moves and jumps.

Wheels

[edit]Polyurethane wheels

[edit]Modern inline wheels are made of polyurethane, a material that revolutionized skating. Before the widespread adoption polyurethane, roller skates and skateboards used composition wheels made from clay or rubber mixed with sawdust and other fibers. These composition wheels were prone to swelling from moisture and could shatter on impact, contributing to a decline in skateboarding by the late 1960s.[20][129][130][131][P]

In the early 1970s, roller skaters experimented with polyurethane wheels, but they proved too grippy and slow for roller rinks with wooden floors, where composition wheels performed better. However, by the mid-1970s, skateboarders repurposed polyurethane wheels from roller skates, shaving them down to fit skateboards. These wheels excelled on streets and urban terrain, offering greater durability and impact resistance compared to their predecessors. Their elasticity provided a smoother ride over rough surfaces, helping to spark a resurgence in skateboarding after its late-1960s slump.[134][135][136]

In the early 1980s, Scott Olson similarly repurposed polyurethane wheels from roller skates, shaving down tens of thousands to fit the skates sold by his company, Ole’s Innovative Sports – later known as Rollerblade. The same qualities that made polyurethane wheels ideal for skateboarding, such as durability, impact resistance, and a smooth ride, also benefited inline skating. This innovation helped bring inline skating out of obscurity and transform it into a popular outdoor sport during the 1980s.[137][29][20][138]

What truly set polyurethane (or urethane) apart from previous wheel materials was its versatility. As an elastomer, it could be molded into any shape and formulated to achieve a wide range of properties including color, hardness, grippiness and rebound. This adaptability allowed for the development of specialized wheels for different inline skating disciplines, from large, hard wheels with pointed bullet profiles for outdoor racing to small, soft wheels with rounded profiles for indoor hockey.[139][138][37]: 20–26 [Q]

Another remarkable aspect of a polyurethane compound is that it can be formulated to achieve high elasticity, regardless of the desired values for other properties such as hardness. In material science, this elasticity is often measured with the Bayshore Resilience test. In the inline skating industry, it is referred to as wheel rebound. A wheel with high rebound efficiently converts energy from a skater's stride into acceleration, while a wheel with low rebound dissipates much of that energy, leaving little to propel the skater forward. High-rebound wheels are beneficial across all inline skating disciplines, enhancing performance and efficiency.[141][R][37]: 24–26

Wheel structure

[edit]From the 1910s to the 1970s, many wheeled skates served as precursors to modern inline skates. Most of these early skates featured small wheels made of rubber or rubber reinforced with fibers, often with relatively simple constructions. In many cases, the wheel was merely a rubber ring shaped like a donut, with a bearing cylinder press-fit into its hollow center – an example of which can be seen in the 1966 Chicago Roller-Blade.[19] Other designs incorporated two metal discs to enclose the bearing cylinder more securely within the rubber wheel, as seen in the 1975 Super Sport Skate.[21]

These early rubber wheels were designed to flex under load, providing grip on road surfaces. Nevertheless, the same elasticity that enhanced their performance also made them increasingly unsuitable for securely housing precision ball bearings, which inline skates began adopting from roller skates in the 1980s. A misaligned bearing could cause the wheel to tilt, resulting in constant dragging against the frame. This friction not only impaired performance but also generated heat, which could soften the wheel and further compound the misalignment issue.[142][143]

To address this in roller skates, metal bushings were introduced to hold two ball bearings and a spacer in precise alignment at a 90° angle to the wheel axle. While effective, these bushings added weight and introduced new issues such as metal grinding noises. As plastic became more common, metal bushings were replaced by injection-molded plastic hubs. These single-piece hubs not only securely encased the bearing assembly but also interlocked with the elastic wheel without additional hardware. Furthermore, plastic hubs reduced overall wheel weight, unlike metal bushings, which increased it.[142]

In the 1980s, Rollerblade collaborated with Kryptonics to develop polyurethane wheels for inline skates. The inline industry adapted hub innovations from roller skates, integrating them into inline wheels. These wheels were manufactured by placing a plastic hub at the center of a mold and then pouring molten polyurethane around it. The liquid polyurethane flowed into cavities and holes in the hub before settling. As it cooled and solidified, it formed a secure interlock with the hub.[N][103][Q][S]

Modern inline wheels consist of two main components: an outer polyurethane tire, shaped like a donut, and an inner plastic hub, also known as a core. The hub features a hollow center designed to accommodate a spacer and two ISO 608 ball bearings. Made of hard plastic, the hub securely holds the bearings in place through a friction fit - something the softer polyurethane tire cannot achieve. On the other hand, the soft polyurethane tire is able to deform upon ground contact, cushioning the landing and gripping the ground.[103][Q][45]

Wheel hubs

[edit]The outer rim of the hub, known as the interlock, is buried within the polyurethane tire. Unless the tire is made from clear urethane, this rim remains hidden from view. Its size, shape, and design vary depending on the wheel’s outer diameter and the demands of different skating disciplines. Beyond mechanically securing the tire to the hub, the interlock rim also enhances the wheel’s overall structural rigidity.[T][S][144][145] Some manufacturers apply a bonding agent to the hub before pouring the polyurethane, creating a chemical bond that reduces reliance on mechanical interlocking. Others use polyurethane-blended plastic hubs, such as "Estaloc," developed by Robert J. Labeda of Labeda Wheels in collaboration with B.F. Goodrich, which chemically bonds with the polyurethane tire during the molding process.[Q][146]

The visible portion of the hub varies in size depending on the wheel’s overall dimensions and the requirements of specific skating disciplines. In some small wheels used for aggressive skating, the visible hub may appear as a thin ring between the bearings and the tire, just large enough to serve as a bearing housing. In contrast, larger racing wheels from the 1990s, typically around 82 mm in diameter, often featured hubs occupying nearly 50% of the wheel’s diameter. By the 2020s, even larger wheels from 110 mm to 125 mm feature hubs that take up most of the wheel’s diameter.[43]: 19–24 [37]: 26–27 [145][147]

As wheel sizes increase, so too do their visible hubs. A solid polyurethane wheel of substantial size would be prohibitively heavy and excessively flexible, making it impractical for inline skating. To address this, large inline wheels adapted design principles from polyurethane stroller wheels, incorporating lightweight yet rigid spoked hubs with an interlock rim to secure the polyurethane tire. These spoked hubs, also known as open cores, feature an outer rim connected to the bearing housing by distinct spokes. In contrast, a full hub, also referred to as a closed core, consists of a solid disc with no clear separation between the outer rim and the bearing housing. Between these two designs is the semi-open core, which features a solid disc but with small hollows drilled between the outer rim and bearing housing to reduce weight.[148][145][37]: 26–27 [138]

Spoked cores are generally lighter than full cores but may offer reduced rigidity and structural integrity. As a result, aggressive skaters typically favor small wheels with robust full cores to ensure durability against the high impact of jumps and landings. Conversely, speed and marathon skaters prefer large wheels with spoked hubs, as the open core design allows air to circulate around the hub, helping dissipate heat generated by the bearings during prolonged high-speed use. Without adequate heat dissipation, the polyurethane tire may soften, increasing deformation during rolling and potentially leading to separation from the hub.[138][45][103][149]

Wheel diameter and profile

[edit]

Inline skate wheels in the 2020s range from as small as 55 mm to as large as 125 mm in diameter.[150][145] However, their width remains industry-standard at 24 mm, regardless of size. Wheel frames are designed for specific setups, accommodating a set number of wheels of particular diameters. Despite these variations, all frames assume a uniform 24 mm hub width and polyurethane tires no wider than 24 mm.[45][143][151]

Wheel profile refers to the shape of the wheel’s contact surface when viewed head-on, that is, the portion of the wheel that touches the ground. While any wheel diameter can, in theory, be paired with any profile, certain combinations prove optimal for different skating disciplines.[151][152]

Some inline wheels feature a flat contact profile, resembling car tires with a rounded rectangular shape. This shape provides a stable upright rolling experience with a strong grip on the ground, due to the larger surface area. Flat-profile wheels work well for disciplines that keep skates upright while rolling, such as aggressive skating.[149][143] Typical aggressive wheels are relatively small, ranging from 55 mm to 64 mm in diameter. Grindwheels, installed as middle wheels, are even smaller, typically under 50 mm. Made from hard polyurethane or plastic, they have reduced traction to minimize wheel bite during a grind. However, where grip is needed, such as during stair bashing, the flat profile’s large contact surface helps compensate for the grindwheels' inherently low traction.[153][81][150][57] In the 1990s, aggressive wheels and grindwheels trended toward completely flat profiles. However, in the 2020s and beyond, aggressive skaters began favoring wheels with slightly rounder profiles, offering a balance between stability and maneuverability.[152]

Most inline wheels have a round profile rather than a flat one. This is because skaters don't always roll with their skates perfectly upright. Much like ice skating with blades, many inline skating techniques involve edging - that is, skating on the side of the wheels. This requires the skate to tilt at various angles, depending on the move being performed.[D][49] A round profile maintains a consistent, usable contact surface across different edging angles, even if that surface is smaller than what a flat-profile wheel provides when fully upright. Disciplines like inline hockey and freestyle slalom typically favor round-profile wheels of smallish to medium size, with diameters no larger than 80 mm.[151][152][145]

At the opposite end of the spectrum from the flat profile is the bullet profile, also known as the pointy, thin, narrow, or elliptical profile. This shape is usually found in larger wheels ranging from 90 mm to 125 mm in diameter. The combination of a bullet profile and large diameter serves the unique demands of speed skating, where racers aim to satisfy two seemingly conflicting goals.[38]: 51–52 [138][152][52]

The first goal is to maximize static friction between wheel and ground during the stride phase with a deep edging angle, converting as much energy as possible from a lateral push-off into forward kinetic motion. The bullet profile supports this by offering a generous contact surface when the skate is deeply tilted, effectively extending the power phase of the stride, covering a large striding distance.[45][66]: 316 The second goal is to minimize rolling friction, more appropriately called rolling resistance, during the glide phase. When the skate returns to an upright position, the bullet profile offers a small point of contact with the ground, reducing rolling resistance and enabling longer, faster glides with minimal energy loss.[45][66]: 316

In addition, large wheels function like flywheels, storing substantial rotational energy, which helps the racer reach and maintain high speeds over long distances. The gyroscopic effect of these large spinning wheels further enhances efficiency by stabilizing the skate’s direction, promoting straight-line tracking and reducing energy lost to unwanted lateral drift. However, this benefit comes with a trade-off: larger wheels have greater mass, which makes them harder and slower to accelerate.[45][37]: 24–25

In contrast, small wheels are easier to accelerate due to their lower rotational inertia, enabling faster starts and quicker maneuvers. They also lower a skater's center of gravity, improving control and stability. However, smaller wheels can result in a bumpier ride, as they struggle more over obstacles like bumps, cracks, sticks, and pebbles.[138][79][150]

Wheel hardness and deformation

[edit]

Polyurethane wheels deform under the weight of the skater, and a certain amount of deformation is desirable because it increases the contact area between the wheel and the ground, enhancing grip. This deformed contact area, often referred to as the footprint in the literature, differs slightly from the profile of an unloaded wheel.[143][46][45] The ideal amount of deformation depends on the skating surface. On smooth, slippery indoor rinks with polished wood floors, softer wheels are preferred, as their greater deformation allows them to mold to the surface and improve traction. In contrast, outdoor roads with asphalt surfaces call for harder wheels that deform less, since the naturally rough texture of the ground already provides sufficient grip with minimal footprint.[75]: 18–19 [147][154][43]: 21

Achieving the right balance of grip is crucial. Too little grip can cause the skater to slip during the stride phase, wasting energy without translating it into forward motion. On the other hand, too much grip creates excessive rolling resistance, which quickly saps speed during the glide phase.[45][46]

In general, softer wheels generate more rolling resistance due to their greater deformation, while harder wheels require less effort to start rolling and maintain speed on smooth surfaces. However, rolling resistance is also influenced by the roughness of the terrain. When a hard wheel rolls over a bumpy surface, energy is wasted as it repeatedly lifts the skater’s weight over each small surface imperfection, offsetting some of the advantages typically associated with hard wheels, such as quick acceleration and higher sustained speed. In contrast, the smoother ride provided by softer wheels can help absorb these irregularities, reducing energy loss and partially compensating for the speed sacrificed to deformation.[155][156][157][158]

The actual degree of wheel deformation is influenced by three main factors: the skater's weight, the wheel's intrinsic hardness, and its current temperature. A skater’s weight remains relatively constant, and wheel hardness is fixed at the time of manufacture. However, wheel temperature varies; it is influenced by ambient conditions, heat absorbed from rolling over warm surfaces, and heat generated by the bearings during prolonged high-speed skating. As wheel temperature rises, the polyurethane softens and deforms more easily, temporarily reducing the wheel’s effective hardness.[N][159][45]

Wheel hardness is measured using the Shore durometer type A scale, which is designed for relatively soft materials. The scale ranges from 0A (the softest) to 100A (the hardest). Inline skate wheels typically fall between 72A and 95A, depending on their intended use. Indoor hockey wheels are among the softest, usually rated between 72A and 78A. Outdoor wheels for recreation use slightly harder compounds, typically ranging from 80A to 84A. Freestyle slalom and urban skating wheels fall in the medium-hard range, from 83A to 88A. At the upper end, aggressive skating wheels are some of the hardest, rated between 88A and 95A.[43]: 21–22 [151][154][147]

Within the suitable hardness range for a given activity, skaters would choose wheels at the softer end to benefit from improved grip, which allows for quicker acceleration during lateral strides. Softer wheels also offer a more comfortable ride on uneven surfaces, as their greater deformation helps absorb vibrations and reduces energy loss. But this comes at the cost of faster wear. Conversely, wheels at the harder end of the range enable skaters to reach and maintain higher top speeds during gliding. Harder wheels are more resistant to wear on rough surfaces and provide a more direct, responsive feel. But this can result in a bumpier ride and some loss of energy.[138][160][147]

Dual density wheels

[edit]For nearly two decades after polyurethane wheels became standard on modern inline skates, skaters faced a difficult compromise: selecting a single wheel hardness to balance two conflicting sets of needs. On one hand, softer wheels were desirable for shock absorption over rough terrain and for maintaining grip at deep edging angles. On the other hand, harder wheels offered better wear resistance on abrasive surfaces and allowed for higher top speeds while gliding upright. Skaters had to weigh these trade-offs carefully, as no single hardness could perfectly satisfy both demands.[155][161][45]

In 1997, K2 filed a patent for what it called a dual durometer wheel - later known in the industry as a dual density wheel - designed to offer the comfort of a smooth ride over rough terrain without sacrificing the key advantages of hard wheels: wear resistance and high top speed. Unlike conventional wheels made from a single polyurethane compound, this design featured two layers: a hard outer tire, typically rated between 70A and 100A, and a soft inner ring, rated between 20A and 75A. The compressible inner ring absorbed shocks and vibrations, while the hard outer layer maintained durability and top speed.[155]

That same year, Neal Piper and Tom Peterson of Hyper Wheels filed a patent for a similar concept, but with a key difference: instead of using a soft polyurethane ring, their design featured an inner foam mandrel with a triangular cross-section. This approach aimed not only to deliver the same advantages offered by K2’s dual-durometer wheels, but also to enhance grip during deep edging. The foam mandrel was encased in an airtight skin, which shaped load-bearing side walls in the hard outer tire. The triangular foam shape preserved the tip of the wheel profile from deforming when skating upright, while allowing the sides of the profile to deform under the angled loads of striding and turning at around a 30° tilt, improving grip during these maneuvers.[46]

In 2004, Neal Piper, widely regarded as one of the most influential skate wheel chemists,[45] filed a patent for a multi-density wheel that approached the same problem from the opposite direction of his earlier 1997 Hyper Wheels design. Instead of using a hard outer layer with a soft inner ring, this new design featured a soft polyurethane outer layer, typically rated between 60A and 75A, molded over an internal support structure made from much harder materials, usually rated between 80A and 95A or even higher. The concept first materialized as the Revision Variant hockey wheels, and later evolved into the Recoil and Flex product lines. These wheels allowed hockey players to achieve top speed without sacrificing high grip.[162][163]

Wheel rebound

[edit]

Wheel rebound refers to the amount of energy a polyurethane wheel returns as it recovers its shape after being deformed by weight or force. While the term is commonly used, there is no consensus on how to consistently measure and publish rebound ratings. However, the relative rebound of different wheels can be easily compared by dropping them from the same height and observing how high each one bounces back from the floor.[37]: 24–26 [43]: 21–22

Rebound is a universally-desirable trait, unlike other wheel characteristics that must be carefully chosen to suit a skater’s style, terrain, and preferences. Across all disciplines and surfaces, the higher the rebound, the better. Such is not true of diameter, profile, or hardness. If cost were no concern, skaters would always choose the wheels with the highest rebound.[154]

A high-rebound wheel feels lively, snappy, and responsive, while a low-rebound wheel feels dead. Skaters on high-rebound wheels roll faster and with less effort, as more of the energy generated by each push against the ground is returned by the wheels and converted into forward motion. In contrast, low-rebound wheels behave more like flat tires; they absorb energy rather than returning it, forcing the skater to work harder to maintain speed, much like walking on soft sand.[141][159]

A polyurethane compound can be formulated to exhibit a wide range of rebound characteristics, independent of its hardness. These are distinct properties of a polyurethane wheel. Hardness determines how much the wheel deforms under load, such as the compression caused by a skater’s weight. Rebound refers to how much of that deformation energy is returned to help propel the skater forward.[R][45][37]: 24–26

Rebound can be measured in several ways, including the Bayshore Resilience test and the Rebound Resilience test. The former calculates the ratio of rebound height to drop height, while the latter measures the percentage of energy returned after an impact. When applied to polyurethane, these tests are often described collectively as measuring polyurethane resilience, an industry term synonymous with rebound. Although both tests aim to quantify a material’s elasticity, their results are not directly comparable or convertible. In the context of inline skate wheels, rebound is rarely specified in technical datasheets. When it is, it’s typically presented using vague, consumer-friendly labels such as High Rebound (HR), Super High Rebound (SHR), or Ultra High Rebound (UHR).[141][164][143][154][145]

In mechanics, rebound is often characterized by its complementary property, elastic hysteresis. Rebound refers to the amount of energy a wheel returns after deformation. On the other hand, elastic hysteresis measures the amount of energy lost, typically as heat, during the deformation and recovery cycle. These two properties are inversely proportional: a wheel with high elastic hysteresis dissipates more energy as heat when compressed and released, resulting in lower rebound.[165][141]

Rolling resistance

[edit]

Rolling resistance is often the main factor limiting a skater’s ability to reach top speed. Also known as rolling friction or rolling drag, it refers to the force that opposes the rolling motion of the wheels as the skater glides across a surface.[66][46]

Several factors influence rolling resistance, but the most significant is typically elastic hysteresis. Recognizing its impact, all reputable wheel manufacturers formulate polyurethane compounds to deliver high rebound and thus low elastic hysteresis. This is particularly crucial in speed skating, where maximizing top speed is the primary objective.[156][75]: 18–19 [66]: 316

The weight of the skater and the hardness of the wheel together determine the degree of wheel deformation and the resulting increase in footprint under load. Footprint is another key contributor to rolling resistance. In general, speed skaters favor hard wheels with a pointy profile, which create smaller footprints and therefore minimize rolling resistance when skated upright. The desire to reduce gliding footprint while maintaining comfort led to the development of dual-density wheels.[46][66]: 316

The roughness of the terrain is another key contributor to rolling resistance. As a wheel rolls over a bumpy surface, energy is lost in repeatedly lifting the skater’s weight over each small imperfection. The need to cushion bumpy rides without increasing the wheel’s footprint under load was a major driving force behind the development of dual-density wheels.[157][156][155][158]

Wheel diameter is another important factor in rolling resistance, particularly on rough terrain. In general, larger wheels roll more easily over uneven surfaces. Increasing wheel diameter reduces the coefficient of rolling resistance by decreasing the angle of incidence between the wheel perimeter and surface imperfections. In other words, a larger wheel can bridge bumps and irregularities more smoothly, resulting in less energy loss and easier rolling. This is why relatively large wheels, typically ranging from 90 mm to 125 mm, are commonly used in urban skating and marathon skating, where both speed and the ability to handle imperfect surfaces are essential.[158][157][52]

Bearings

[edit]How bearings work

[edit]Ball bearings enable inline skate wheels to rotate freely and smoothly. The adoption of modern ISO 608 ball bearings, combined with polyurethane wheels, helped propel inline skating to peak popularity in the 1990s.[166][137][41]